Author: Prof. Roger West, School of Engineering, Trinity College. September, 2022

Novel, low carbon precast sandwich panels for retrofitting, or re-cladding building facades were investigated by a consortium of European partners including UCD, TCD and industrial partners, Techrete. This blog, the second of two will deal with the composite structural action of such panels, whether load-bearing thick panels (such as in figure A below, with a thick inner wythe connected by shear collectors, shown in blue), or thin self-supporting panels (with two thin wythes), which only have to withstand lateral loads, particularly wind loads.

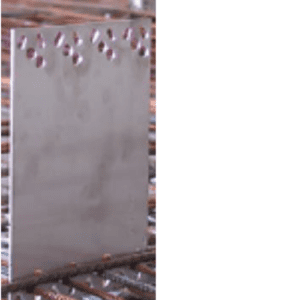

The panels, which could be up to 4m in length, are expected to have flexural resistance by developing composite action between the inner and outer wythes, separated by a thick layer of rigid insulation (shown in yellow in figure A), strengthened by a small number of shear connectors suitably embedded into each wythe. These connectors can be stiff and strong such as steel plates, or concrete webs, reinforced with steel bars (figure B), although these are thermally conductive and compromise the thermal efficiency through bridging. This arrangement of connector develops good composite action allowing shear transfer between the wythes under flexure. Alternatively, non-conductive, but less structurally efficient fibre reinforced polymer continuous grids or pins (figure C) have become more popular when high thermal efficiency is required.

Of particular interest here is the ability of these shear connectors to transfer load between the exposed outer wythe and the inner wythe such that efficient composite action in flexure is obtained. When a simply supported thin panel is laid flat and tested in flexure using displacement control, the response, as determined by the load-central deflection plot, as illustrated in figure ‘D’ below, then if steel plates are used for shear connection, almost perfect shear transfer between wythes would result (shown by the steep dashed black line). If no shear connectors exist at all, then the insulation would be responsible for transferring the load between the wythes, in compression, and the wythes would act virtually independently of each other, as shown by the red line. As may be observed, the panel would be much more flexible and would sustain much lesser loads.

On the other hand, if the non-conductive connectors are used, the behaviour is much more complex. Up to the point of the first concrete crack, the pinned connector enhances the load share between the top and bottom wythes by going into compression due to its superior axial stiffness – as seen by the blue curve in figure d. In contrast, the thin grid connector has very low axial resistance and so it effectively buckles under the compressive load between wythes and, as can be seen in the green curve in figure d, has a lower flexural stiffness overall than the pin connectors panel.

But this propensity to resist flexural loads for the non-conductive connector panels is reversed when the upper wythe concrete cracks at between, 1mm and 2mm deflection in the example shown above. Now, the lateral shear in composite action dominates and the discrete pin panels lose load capacity and have reduced flexural toughness due to the two wythes sliding laterally relative to each other due to the small lateral movement resistance offered by the vertical pins embedded in the concrete wythes, again as observed in the blue line’s response in figure d. In sharp contrast, the grid connected panels not only sustain the load, but allow an increased load capacity with increasing displacement as a trussed action develops between the wythes, the compression being resisted by the rigid insulation and the tension by alternate strands of the diagonal grid in tension, responding as shown in green in figure d.

The conclusions are that the cracking resistance of the non-conductive shear connected panels is inferior to the conductive connector panels, and the grid type connectors have better post-cracking load capacity and toughness compared to the pin type connectors, despite having similar first crack load capacities.

It should also be noted that in the case of non-load bearing panels which have equally thin wythes, the load transfer through the insulation with pin connectors suggests that the inner wythe takes a larger proportion of the load because the outer wythe is effectively floating on the insulation, while the inner wythe is more rigidly supported by the panel connector fixed to the building behind. The possibly consequence is that the inner wythe might crack while the damage remains unseen from the outside.

These considerations require the structural engineer to allow for a lesser structural performance while attaining the improved thermal performance which non-conductive shear connectors facilitate, especially if the lower carbon thin panels are used.